PAST PROJECTS

Cornubia (1911)

Cornubia is a stunning example of one of the original “Bristol Channel Pilot Cutters”. Built in 1911 at J Slades & Sons, Polruan, Cornwall. She sailed was operated out of Barry on the north side of the Bristol channel as “Barry Pilot 25” until 1920.

During the Saturday race of the 2025 Antigua Classics Regatta, the 114 year old pilot cutter broke the pivot on the gaff saddle causing the yard to become detached. Fortunately the wind was un-customly light and the sprightly and alert crew noticed before any further damage was caused.

With a race the next morning, Cornubia’s hopes to stay on the podium diminished. In conversation with their neighbor, the equally illustrious “Ticondaroga” suggested they call us.

Within 30 mins we had our fabrication shop open and the yard and saddle back to the shop. Within another hour we had fixed the assembly and substantially beefed up the connection. It was back on the charming cutter by dusk and she was back out racing in the morning.

The owner of Cornubia noted “We called their emergency number at 3pm on a Saturday. They opened up the workshop for us, collected the gaff, fixed it, and returned it within a couple of hours. Quality repair with a smile at a reasonable cost.”

Baton Rouge

The 205ft yacht “Baton Rouge” built by Icon Yachts, and designed by Tim Heywood and Redman Whiteley Dixon, is a repeat customer of Woodstock.

Because of this, when Baton Rouge required some fine parquet curved faces of the bar on the sky deck to be repaired there, was only one company to call.

Baton Rouge has traveled worldwide through various climates and weather conditions, and the persistent moisture from the refrigeration units caused the edges around the grilles to gradually darken and soften over an extended period. Because the wood was originally purchased many years ago from a distant plantation, finding new matching wood was unfortunately not an option. To address this, we decided to carefully remove the damaged sections, reinforce and cover the end grain with teak, and craft completely new custom grilles recessed into the parquet fronts. Our experienced in-house team meticulously designed the grilles using CAD software, and we used Creative Waterjet Corp to precisely cut each piece before delivering them back for final fitting and installation.

Through every stage—from careful material selection to precision cutting and expert fitting—the repair upheld the highest standards of craftsmanship, ensuring that Baton Rouge's elegance remains uncompromised.

EOS

Storming along

The magnitude of EOS’s size and opulence is hard to comprehend until you have had the priviledge of being onboard.

EOS has been coming to Woodstock since she was built and as she is maintained and improved to the highest standards, we make every effort to cater for her varying never ending needs.

During her most recent visit to our beautiful shores we sand blasted and painted one of her tender cradles, repaired the compound curved base to one of her many pillars, repaired some of the deck head collars of the same pillars, improved her working tenders storage spaces, fabricated a one piece strike plate and holder for the bridge door opening mechanism, replaced part of the margin board on her swimming gate and even crated and moved a piece of art for her (under the expert guidance of Sarah from Artpack).

A day in the life of EOS is never the same as the one before. We look forward to meeting the next interesting challanges she brings to us.

Bequia

Bequia, built by our friends at the famous Brooklyn Boatyard in Maine, succumbed to the infamous St Barths surge so much that one of her aft cleats lifted from the deck, and pulled it into the fairlead causing damage to the bulwark and cap rail.

In consultation with Brooklyn Boatyard and Stephen Waring Design a plan was made to not only rebuild the bulwark but strengthen it as well.

This was done with a new bulwark section made of opposing scarfs (inside and out) making the repair immovable from either direction. These scarfs were then further reinforced by feathered G-10 plates on either side. The whole lot was bolted from the top to ensure this part of the bulwark is significantly stronger than originally built. The new section of cap rail was then fastened on top of this and varnished. Hopefully Bequia’s bulwark will never again succumb to “the surge”.

Malolo

© Arthur Daniel

Malolo (ORC 50) came to us because their high-aspect foils did not meet the stringent quality standards required by a top-level racing team. The 4-meter foils needed a complete refurbishment, which involved stripping off the old gelcoat and recoating them precisely with Epoxy Graphite. To ensure accuracy, we reached out to the designers to obtain detailed drawings and the corresponding NACA foil profiles. These were then meticulously converted into a 3D CAD file for better precision. Our trusted partners at Antigua Boatbuilding and Carpentary (ABC) used this digital file to CNC cut highly accurate templates. With these templates, we hand-shaped both foils to perfection, significantly enhancing their performance and fit.

Additionally, the boards were fitted with stainless steel pad eyes that had been causing damage to the daggerboard bearings during use. To resolve this issue, our skilled machinists crafted custom Delrin inserts featuring two different diameters—one specifically designed to fit the Dyneema lines and another to accommodate the dogbone hardware from A & A Rigging on the ends. These inserts were given a knurled finish, which ensured a much better grip inside the boards, preventing unwanted movement and providing peace of mind that they are secure.

Remarkably, just one week after Malolo received the upgraded boards back from us, they went on to win the multihull class at the prestigious 2025 RORC 600 race, demonstrating the tangible performance improvements achieved through our work.

Tilly XV

Tilly XV (1912) is a wonderful and interesting craft. Built for the Prince Heinrich von Preussen, one time commander of the Russan Baltic Fleet, brother of Kaiser Wilheim the 2nd and grandson of Queen Victoria she is illustrious as she is unique.

Built in Germany to the one design Sónderklasse or “Special Class”, she is 12m Length overall (LOA) but only 5.8m length on the waterline (LWL)! At the time of her build in 1912, she would have been one of the most extreme designs of her day.

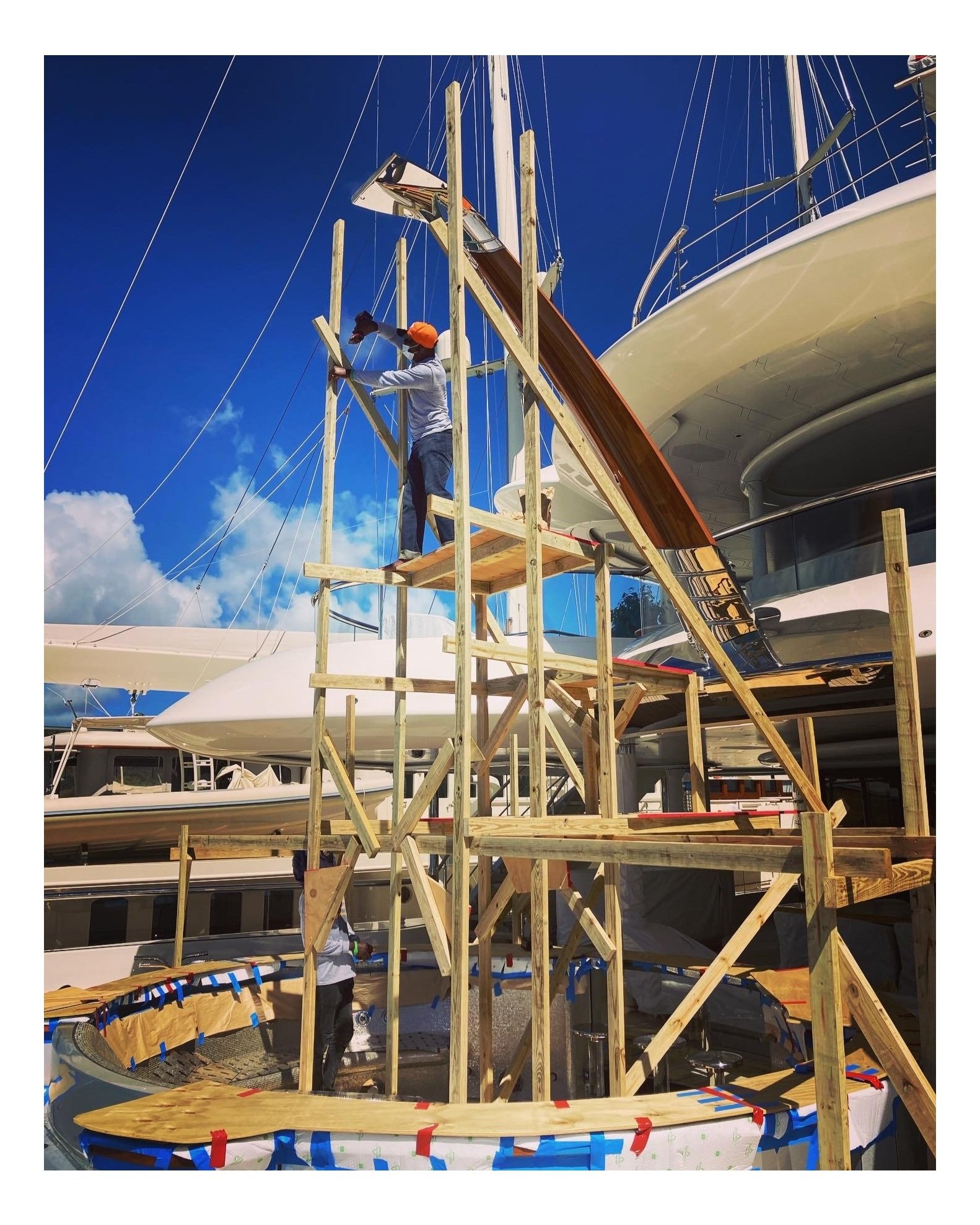

Unfortunately, during the Antigua Classics, whilst surfing at 14kts on an Atlantic swell, a shackle failed on the cap shroud causing the mast and 50sq m of sail to fall to the deck. Vey fortunately, no one was hurt.

As this was the first day of racing, Tilly XV was in dire straits. Luckily Tilly XV was pointed in our direction and we fixed the mast within 24hrs (and a gallon of coffee) and she managed to see out the rest of the regatta without harm. As far as we know, our repair is still holding strong and she has gone on to win prestigious regattas on both sides of the Atlantic.

Prevail

The Bill Tripp “Cafe Racer” came to us as a repeat customer as they knew we could achieve the high quality, high finish in Carbon that the owner required.

As a streamlined all carbon machine built and designed to be “photo friendly” on the water, the builder had not included any chafe protection for her gunwales from lines. This had led to chafe marks in her beautiful custom metallic paint job.

To counter this ommission. Woodstock designed and built removable custom chafe pads in carbon twill with a neoprene backing which fitted over the flush NOMEN cleats when in use.

Whilst she was with us we also fixed a hairline crack in her carbon wheel caused by an errant line, and made an quickly removable “sailing bimini” using seasmart carbon poles and fittings. She sailed away a happy customer with the skipper stating “I couldn’t be more happy with the attentive way that woodstock dealt with all our queries and requests and topped it off with an A1 job”.

The Grove Residences

In the summers when Antigua becomes sleepy with the heat, we like to take on projects we might not have time for in season. These are not only on the water but on land as well.

When the client approached us to do the metal and woodwork on their new luxury apartment complex, we lept at the chance to help them create their dream space.

Some of the more unique items we built were a bespoke glass and stainless set of stairs and banister, as well as some modern minimalist custom furniture.

The Grove Residences Project easily dove tailed into the work we do for yachts as the high end joinery, custom metal fabrication and “thinking outside the box” is what we do.

If you fancy a holiday in Antigua, or if you live here and want a weekend away, apartments are available for rent at the Grove Residence and they can be found here https://www.thegroveresidencesltd.com

Shamrock V (JK3)

Shamrock V is one of the great J-Class racing yachts and the only wooden planked J still afloat.

Shamrock V needed some hull resplining and her gold leaf replacing. Of course there was only one place to go for this work. In addition she also required us to make some chocks covered in Elk Hide leather to hold her spinnaker pole which we were happy to do.

Shamrock V is one of only 9 J-Class yachts afloat and she is one of the few originals. Woodstock Boatbuilders is proud to of worked on 8 out if the 9 of these fine machines.

Anna

Anna has been coming to us for modifciations and improvements since she was built at Feadship in 2018.

At 110m LOA, the sheer size of her would be daunting to most, but a job is a job regardless if she weighs 10+ times what the local supply ship does!.

A yacht of this size and complexity requires myriad of skilled craftsmen and women, from engineers for jetskis to shipwrights for deck planks. Metal fabricators for railings and deck fittings, high end painters for paint/varnish work and carbon specialists for goal post repair, thats right, goal post repair!

Anna sailed away happily and returns year on year.