PAST PROJECTS

Cornubia (1911)

Cornubia is a stunning example of one of the original “Bristol Channel Pilot Cutters”. Built in 1911 at J Slades & Sons, Polruan, Cornwall. She sailed was operated out of Barry on the north side of the Bristol channel as “Barry Pilot 25” until 1920.

During the Saturday race of the 2025 Antigua Classics Regatta, the 114 year old pilot cutter broke the pivot on the gaff saddle causing the yard to become detached. Fortunately the wind was un-customly light and the sprightly and alert crew noticed before any further damage was caused.

With a race the next morning, Cornubia’s hopes to stay on the podium diminished. In conversation with their neighbor, the equally illustrious “Ticondaroga” suggested they call us.

Within 30 mins we had our fabrication shop open and the yard and saddle back to the shop. Within another hour we had fixed the assembly and substantially beefed up the connection. It was back on the charming cutter by dusk and she was back out racing in the morning.

The owner of Cornubia noted “We called their emergency number at 3pm on a Saturday. They opened up the workshop for us, collected the gaff, fixed it, and returned it within a couple of hours. Quality repair with a smile at a reasonable cost.”

Baton Rouge

The 205ft yacht “Baton Rouge” built by Icon Yachts, and designed by Tim Heywood and Redman Whiteley Dixon, is a repeat customer of Woodstock.

Because of this, when Baton Rouge required some fine parquet curved faces of the bar on the sky deck to be repaired there, was only one company to call.

Baton Rouge has traveled worldwide through various climates and weather conditions, and the persistent moisture from the refrigeration units caused the edges around the grilles to gradually darken and soften over an extended period. Because the wood was originally purchased many years ago from a distant plantation, finding new matching wood was unfortunately not an option. To address this, we decided to carefully remove the damaged sections, reinforce and cover the end grain with teak, and craft completely new custom grilles recessed into the parquet fronts. Our experienced in-house team meticulously designed the grilles using CAD software, and we used Creative Waterjet Corp to precisely cut each piece before delivering them back for final fitting and installation.

Through every stage—from careful material selection to precision cutting and expert fitting—the repair upheld the highest standards of craftsmanship, ensuring that Baton Rouge's elegance remains uncompromised.

Elysian

Elysian have visited us for a few years straight for various routine maintenance jobs but in this instance came to us with an unusual request.

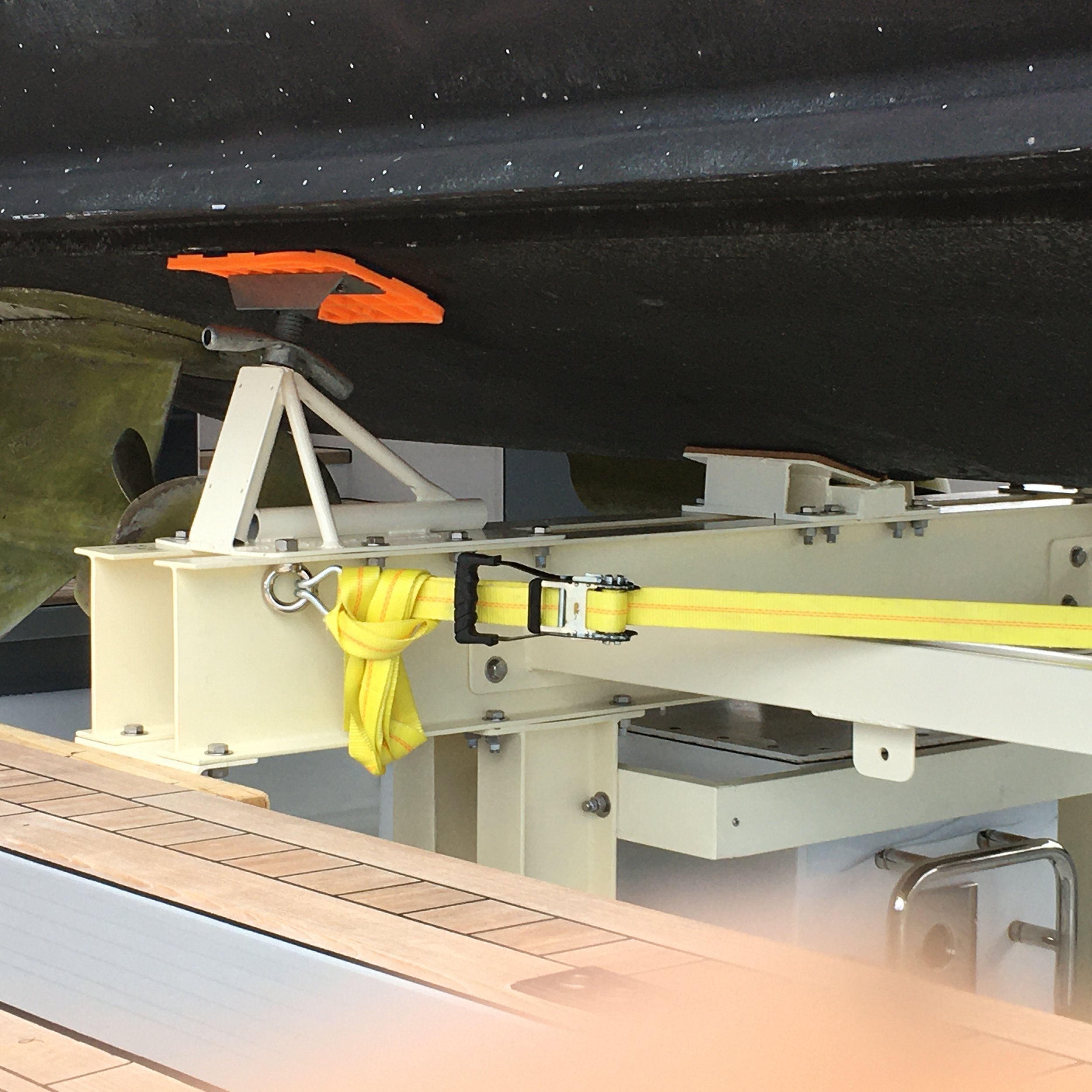

The crew and Owner wanted a non permanant structure to carry their 38ft Wajer tender on Elysian safely when she is offshore on delivery. This would eliminate the external shipping methods they had been using to transport the tender in the past, and would give Elysian a bit more automony to pull into any port big enough for her as she no longer needed to meet the tender or vice versa. The cradle also needed to be able to be assembled or dissassembeled in a matter of hours by the crew and stored on board thus furthering the crews independance from external contractors. A further requirement was that when the cradle is removed, no evidence of the cradle could remain.

Woodstock Boatbuilders, to fill this need, using drawings created by the experienced captain and Naval Architect, built a cradle from recycled I beams which sits in and over the yachts aft swimming pool and around the structures within it.

The cradle has now done 10’s of thousands of ocean miles with the tender still safely in place and the crew happy!